Redefining industrial metallurgy for ease of manufacturing

A platform for all metallurgical process/product improvements & related solutions

Introduction

A Graduate Metallurgical Engineer , worked in various public sectors and private Manufacturing Industries in India and abroad . Practicing Metallurgy since 35+ years . Mr Prasad is only focused on converting scientific innovations to solve day to day problems in Manufacturing Industries. Having worked in reputed manufacturing Industries like TVS Motors, LG Balakrishnan & Brothers, Altair India and Malaysia, Trinity Holdings Dubai, etc, he is able to contribute and help many MSME and small scale industries technically by supporting with innovative idea’s on manufacturing techniques. Expertise on product development, failure analysis, Process design and corrective action. Many of the Industries are supported with ‘Value Engineering’ concept and training the personnel’s on Metallurgical aspect and effect of the process parameters on quality and production repeatability. Completed successfully many turnkey projects

Faculty at

INDIAN MACHINE TOOL MANUFACTURERS ASSOCIATION ( IMTMA), BANGALORE

Member : American Society of Metals. Since 1990

Associate Member : Indian Institute of Metals , Kolkota, India

TURNKEY PROJECTS EXECUTION FOR

HEAT TREATMENT PLANTS (EXPERT IN CQI-9 SYSTEM IMPLEMENTATION AND AUDITS)

FOUNDRY FERROUS, STEEL AND NON-FERROUS (ALUMINIUM, COPPER, LEAD, ETC)

ELECTROPLATING SHOPS

SHOT BLASTING/ PEENING

COLD EXTRUSION PLANT

HOT FORGING PLANT

ALUMINIUM (SAND CASTING, GRAVITY DIE CASTING, PRESSURE DIE CASTING AND LOW PRESSURE DIE CASTING

VENDOR AUDITS FOR SUPPLY OF RAW MATERIALS LIKE ALUMINIUM INGOTS, ALUMINIUM BILLETS, ETC

METALLURGICAL TESTING AND RESEARCH LABORATORIES

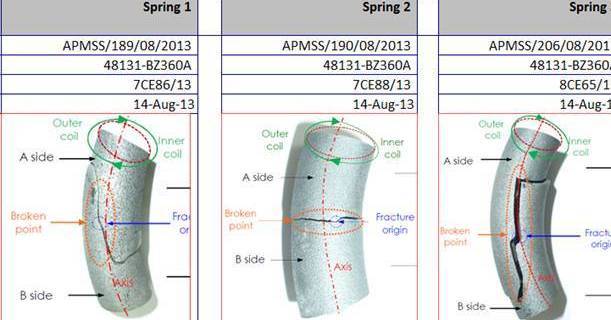

STEEL WIRE DRAWING PROCESSING FOR SPRING STEEL WIRES FOR AUTOMOTIVE SPRING APPLICATIONS

METAL POWDERS PRODUCTION OF FERROUS, (Steel, Alloy steels, Stainless steel, etc.) NONFERROUS,(Copper,Alumunium,Lead,etc), HARDEMETALS (Tungsten carbide, Silicon carbide, etc.)

FERROUS FOUNDRY (Cast Iron, Steel, SG Iron, etc.)

Services

METALLURGICAL TESTING & EVALUATION

We take up evaluation of the metallurgical aspects for new and existing product developments. suggesting the appropriate material for optimum service as per the service requirements of the components . Failure analysis and CAPA for both components and process

Learn More

Ferrous, steel and Non ferrous foundry

We offer solutions for foundries like Turn Key projects up to execution level, Method, Technology, Quality evaluation audits, Process Evaluation Audits, Process consumables,Casting development right from the scratch, Raw material, etc

Learn More

steel wires/Spring Manufacturing technology

We support industries MSME manufacturing steel wires / alloy steel wires for various applications like spring wire manufacturing, Leaf/ coiled springs for their process design especially on different manufacturing process. we take up turnkey projects for complete range of spring manufacturing

Learn More

Heat treatment of Steel, Stainless steel, Aluminium alloys, Copper Alloys, etc

We offer our expertise on Heat treatment process right from Turn key projects to execution, Process design, Failure analysis and CAPA, post heat treatment parameters testing and evaluation, Design furnace to optimal requirement, etc. Auditor and expert in implementation of ISO9001/TS1696/CQI9 system

Learn More

Mining tool manufacturing

We support mining tool manufacturers process requirements like heat treatment, forging and material selection especially on manufacturing activities like DTH Button bits, Hammers, casing and allied parts. Other parts like Drill Rods , cone bits, roller cone bits, etc used in rock drilling, excavations especially on their life consistency and service

Learn More

POWDER METALLURGY

FERROUS POWDERS & ALLOY POWDERS NON FERROUS POWDERS & ALLOY POWDERS INCLUDING TUNGSTEN CARBIDE POWDERS MANUFACTURING TECHNIQUES QUALITY ASSESSMENT AND TESTING MODIFICATIONS ON THE PROCESS FOR ADDITIONAL PRODUCTS POWDER METALLURGY PARTS MANUFACTURING SUPPORT 3 D PRINTING / ADDITIVE MANUFACTURING

Learn Moresurface modifications(patent pending)

MATERIAL DATA :

The Concept of this invention is to use a sufficiently tolerant material for withstanding corrosion at hot temperatures and Heat resistant to melt nonferrous material . There are many such material in the present day market

- Austenitic Stainless Steel special grades like SS 304,SS 310 Etc

Advantages

- Very High temperature resistance

- Very high creep resistance

- Easily fabricated as it is weld able

- Cheapest source of making melting post especially Aluminum Alloy melting

I wanted to improve the working conditions in a nonferrous alloy foundry. When we go through the material data used for making melting crucibles, I understand most of the foundries are using Silicon Carbide Crucibles because the good life . In a manufacturing Industry one should focus on Maintenance free working and repeatable quality. These two are answered using Silicon carbide crucibles. The biggest problem they are facing is increase of melting time over more usage of these Crucibles. As and when the pots are being used for more number of times they pick up Iron. The hydrogen gas evolved during melting of Aluminum deposits Iron in the small pores of the silicon carbide pots and reduce the thermal conductivity of the crucible there by increase the melting time in used crucible it is called aging.

Effect

This increase the required power consumption in electrically heated melting furnace and more gas in gas fired furnaces. It consumes more time to melt the required capacity molten metal.

Discussion

After going through many of the melting practices I was looking for an alternate method to overcome this problem. Ceramic composites are the best suitable material for the properties but the constraint in manufacturing crucibles using this material

Invention

I have taken trials on small scale and achieved very good results

Advantage of the invention

- Manufacturing cost of the crucible is reduced drastically

- The life of crucible will be at least 4 time more than existing stainless steel crucible and same that of silicon carbide crucible

- The weight of the crucible will be 1/3 of Silicon carbide crucible which makes easier to handle crucible especially for a spout pouring

- Heating time will reduced drastically since the wall thickness is very less compared to silicon carbide crucible

- Economically very cheap option since the replacement cost is very much lower compared to silicon carbide crucible

- The problem of decay does not arise since there will no macro porosity as in the case of Silicon carbide crucible there by less power more melting capacity

- Manufacture of crucible for melting all types of nonferrous material

- Manufacture of thermocouple jackets used in corrosive atmosphere

- Usage in some of the Automotive parts to replace stainless steel and reduce cost

- Usage in some of the air craft components for corrosion resistance and higher temperature co

- Usage in Marine parts for withstanding good saline corrosion. Especially to replace cast Iron being used which is heavier compared to coated stainless steel.

- ALUMINIUM AND COPPER ALLOYS MELTING/ HOLDING POTS

- THERMOCOUPLE SHEATHING

- BAILING POTS/ LADLES

- Many more applications like high temperature upto 12000C and highly corrosive atmospheres like Acids, alkaline, Saline atmosphere (sea corrosion),etc

Heat resistant balls(patent pending)

CONCEPT :

The Concept of this invention is to Increase the retention time of the required temperature for a molten nonferrous metal. The normal practice of melting In a nonferrous foundry is done in two stages.

- MELTING

- HOLDING FURNACE/ LADLE

MY INVENTION

I wanted to improve the working conditions in a nonferrous alloy foundry. I wanted to address this problem. Aim was to improve the Temperature holding conditions with small temperature variation even during delay of pouring or casting which saves lot of power. I was looking for a material which can work as a flask for melting crucibles/ holding crucibles. I came across a material which can withstand heat for a long duration and doesn’t react with nonferrous metal.

Discussion

I remember the story for invention of foot wear. Funny isn’t it. I have to narrate once there was a king in those days there were no foot wears. The court yard and palace had protected pathway using Buffalo skin. There was no mess during rainy season. Once king started walking on streets his kingdom he realized that his leg was messy due to mud on the open place. He wanted to give a solution to his people for a common man. He announced to bring maximum amount of buffalo skin cover his whole kingdom. There was shortage of skin and he was worried how to solve the problem. Meanwhile there was a common man gave an idea ‘ why don’t we cover our foot instead covering the whole earth ? ‘ he stitched a foot wear to King . King wore the footwear and was very happy. He gave him lot of gifts and galore. My invention has a small similarity with this story

Invention

The concept is to retain the heat of the molten metal by using a material which has a very high ' Heat content' or ' Enthalpy' heat retention from the center most part of the molten metal ensure very high temperature retention capacity.

I have taken trials on small scale and achieved very good results.

- We have taken trial in a Pressure die casting unit. The workers used to work for 16 hours a day right from morning 6 AM to night 8PM. The time taken for melting 300Kg aluminum is minimum of 4 hours. There was a production loss of 4 hours every day.

- We have introduced heat retention balls . At the end of the shift these balls were placed in the molten metal of the holding furnace. Next day morning the temperature of the molten metal was reduced only by 100 Deg C which was recovered in 1 hour heating.

- The production loss of 4 hours was converted to 1 hour only

- The power savings is up to 30 to 40% on electrical heating furnaces

- The Fuel savings on gas fired furnace is up to 25 to 30%

- Huge power savings on melting and also on holding furnaces

- Temperature variation is only /- 15 Deg C over 2 hours of holding

- The Holding furnace can be made with less bulky and easy to carry to pour in molds especially in sand casting and gravity die casting

Projects completed

Establishment of Data Acquisition and analysis software on a conventional Heat Treatment process -pit type carburizing furnace process facility and salt bath hardening furnaces . Successfully established data acquisition, data analysis, process improvement, Failure analysis, CAPA, process/repeatability and control for a Mining tool manufacturing Industry

Sai Deepa Rock Drills (pvt) LTD, Hyderabad, IndiaMining Tool Manufacturer

Continuous carbo Nitriding furnace facility for manufacturing of Self Drilling hardened screws. Total revamping of the furnace to increase the production capacity . Established carbo-nitriding using LNG as a media gas and LPG for enrichment a new combination of gas atmosphere with proper Carbon potential control. Established a full fledged Metallurgical testing procedure for ensuring life of screws

PRIMA FASTENERS , RAJKOT, INDIA

Established Continuous Heat treatment facility for Bearing race Hardening and tempering, Continuous annealing furnace , Metallurgical testing Laboratory established production, Material handling, Hot forging, validation and approvals as per customer requirement at Scion Exports, Jaipur

SCION EXPORTS PVT LTD, JAIPUR, INDIAAgrasen Engineering Ltd, Jaipur India

Establishment of a new line of Heat treatment facility for a continuous heat treatment furnace for Heat treatment of various automotive components using a Mesh Belt furnace. Continuous mesh belt furnace with a pre-wash, drier, Hardening , quenching and post cleaning facility. Implementation of CQI Heat treatment quality system. Facilities Induction Hardening, Through Hardening, Carbo-nitriding, tempering , polishing, etc

PRECISION HEAT TREATERS & ENGINEERS INDIA PVT LTD, COIMBATOREL G Balakrishnan & Bros, Reynolds chains LTD, etc

Established a Heat treatment facility for Fastener manufacturer. Continuous Hardening furnace with capacity of 1000Kg per hour. Furnace make Sanyung , Taiwan. Facility with pre-wash, drying, Hardening, quenching , post cleaning and tempering on a single line. Process establishment, CQI9 Heat treatment system implementation, Metallurgical testing lab procedures, Component validation at customer end, customer audit and approvals

M.K.Fasteners, BangaloreHyundai, Ford, Bosch, Toyota Boshuku, GM, TVS, etc

Establishment of new steel foundry facility as a turnkey project . Introduced Induction melting facility of capacity 100Kg & 500Kg melting, Pattern shop, Moulding shop, Jolt squeeze, Fettling ,Testing Metallurgical laboratory, Heat treatment, etc. Facility for casting steel grades ASTMA27/27M, ASTMA148/148M, ASTMA217/217M, Cast iron, SG Iron etc. Manganese steel castings etc. Non ferrous foundry for melting Copper alloys, Aluminium Alloys, etc used for Bearing bushes, Engineering Industries, etc.

HADEED ENGINEERING SERVICES FZE , UNITED.ARAB.EMIRATES.ABUDABHI SHIPPING , TRINITY HOLDINGS, RAK CERAMICS, ETC

Established a non ferrous Aluminium foundry with facilities like Pressure Die casting, Gravity Die casting, Low Pressure Die casting and sand casting facility for supplying automotive parts, Decorative castings, Agricultural implements, Machinery parts, Die for synthetic turf manufacturing, Electrical fittings, etc. Capacity of 20Mt per day melting.

PREM INDUSTRIES , BANGALOREHHV PUMPS, GE ELECTRICAL, TVS MOTORS, FORD MOTORS, TOYOTA KIRLOSKAR , ETC

Consultation on a retainer basis to establish vendor quality and new casting development of both ferrous and non-ferrous casting requirements. Inspection of castings at vendor foundry end, Development of new parts castings, Failure analysis, Methods and process development, Training, development of inspection standards, SQC and CAPA requirement for vendor foundry. Presently more than 8 foundries supplying castings. From 2017 to 2018

HHV PUMPS PVT LTD, BangaloreHIND HIGH VAC LTD , BANGALORE

I have successfully completed erection commissioning of water atomized copper powder manufacturing with a rated capacity of 2 Metric Tons per month. This is an additional specialty of manufacturing apart from already existing Electrolytic copper powder plant. We can provide similar services of manufacturing services as a turnkey project. Please contact us

There was a production failure in ' CUPRALLOY , AHMEDABAD' Discoloration of the copper powder after reduction. Mr siddharth has a unique technique of manufacturing copper powder with raw material as scrap copper wires. he has very good facility for manufacturing copper powders and alloy copper powders. we had previlage of solving his problem of discoloration after final reduction. Developed allloy powders like bronze.

CUPRALLOY , AHMEDABADMANUFACTURER OF COPPER POWDERS AND ALLOY POWDERS

Contact

- METEXPERTS METALLURGICAL CONSULTANTS OPC PVT,LTD, 3387,2nd Cross, 6th Main Road, RPC Layout, Vijayanagar Bengaluru - 560040, Karnataka, India

- Near Hampinagar Post office , Vijayanagar Bangalore

- +91-7829721305 - METEXPERT METALLURGICAL CONSULTANTS OPC PVT LTD

prasadlgb - Prasad Rao

prasadlgb - Prasad Rao +91-7829721305 - PRASAD RAO

+91-7829721305 - PRASAD RAO- +91-9611142937 - MEMCON

- prasadrao@metexperts.in

- 09.00 hrs to 18.00 hrs

METEXPERT METALLURGICAL CONSULTNACY is a specialized service that offers expert advice and solutions in the field of Industrial metallurgy. We also often provide training and technical support, helping companies stay up to date with the latest advancements in metallurgical science.

informative

Metexpert profile -al.pdf A complete profile of the company and its functioning

Dew point of a gas.pdf Significance of 'Dew Point' in a gas or gas mixture with examples

Powder Metallurgy.pdf A Synopsis of Metal powder/ Powder parts manufacturing

TESTIMONIALS FROM CLIENTS

MACHTECH ENGINEERING PVT LTD, BANGALORE

Testimony- Machtech.pdf Testimony from customer MACTECH

MEGA MILES LTD, BANGALORE

MEGA MILES TESTIMONIAL.pdfENGINEERING